KINSSON

- Home

- / PRODUCTS /

- KINSSON

AXIAL PISTON FLOW DIVIDER

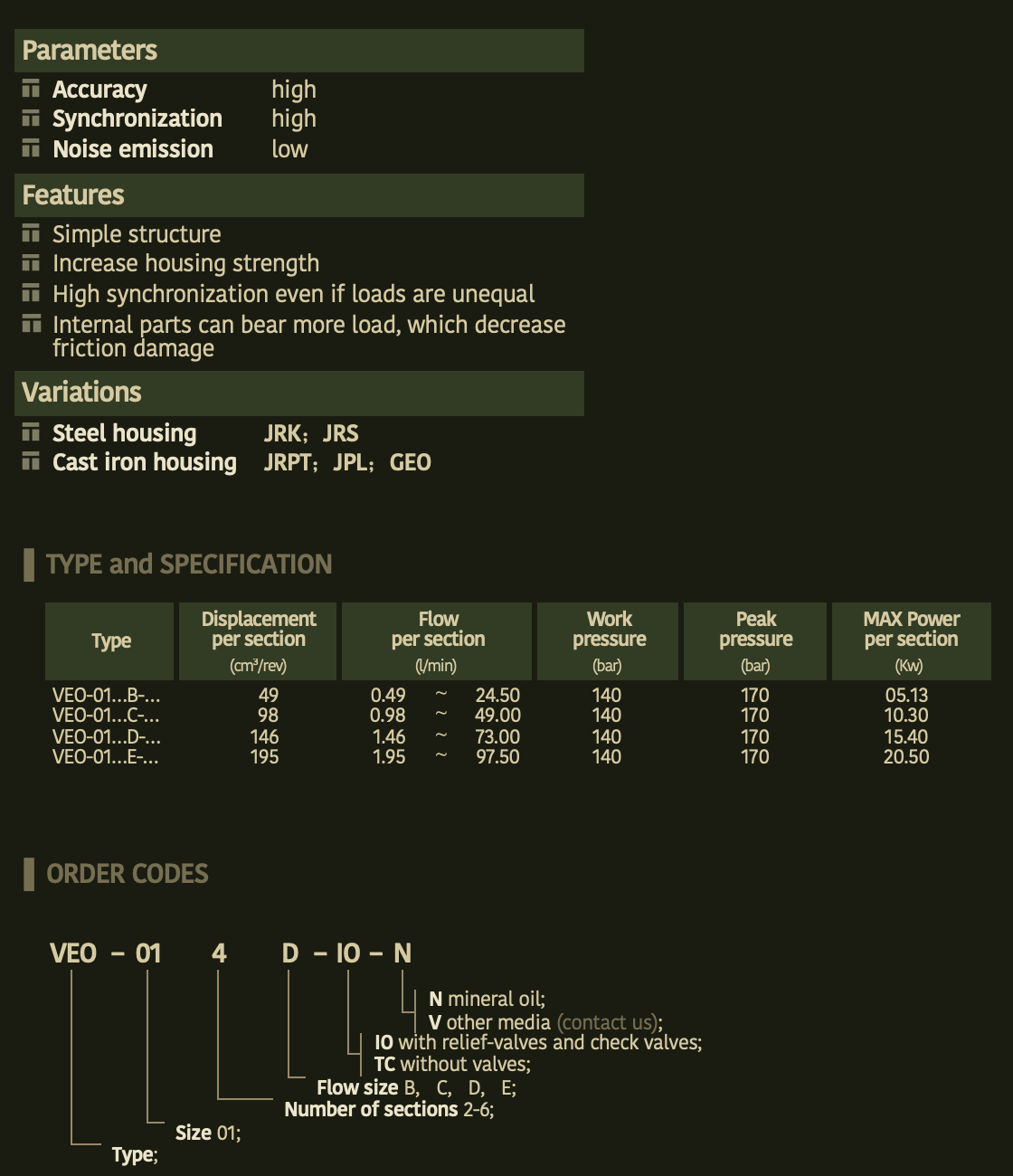

VEO-01

RADIAL PISTON FLOW DIVIDER

VPC-02

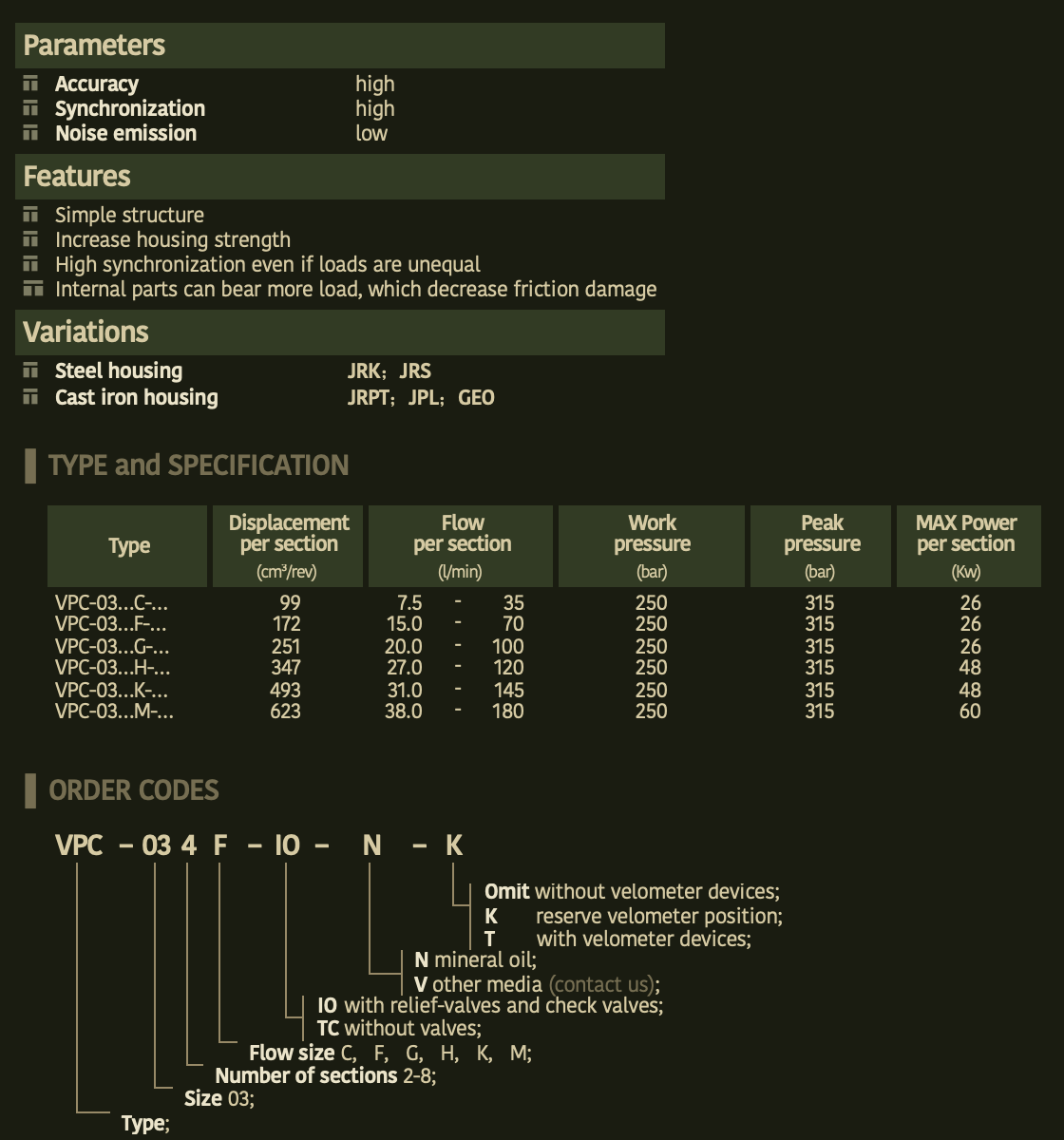

VPC-03

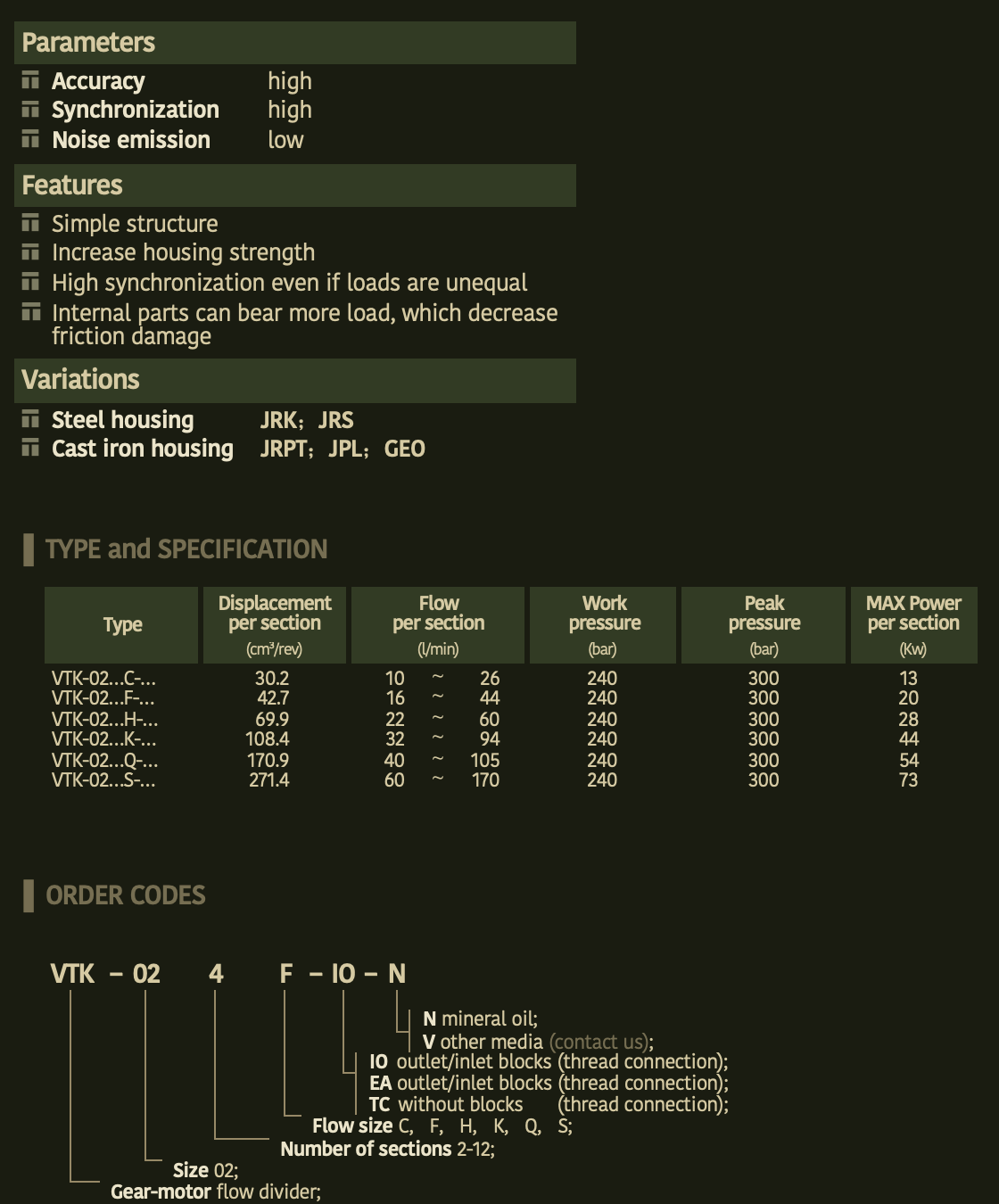

VTK-02

VTR

GEAR FLOW DIVIDER

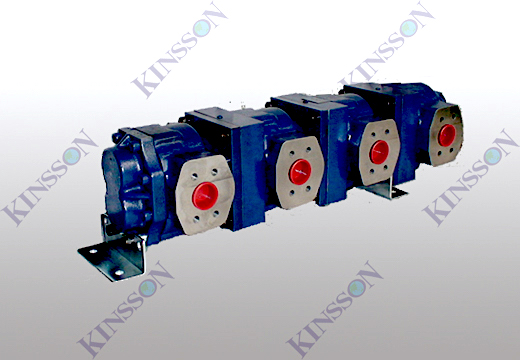

VMX-01

VMX is made of a working section without an inlet or clapboard without an inlet or end cover by progressively adding, and the inlet is on the clapboard on the end cover. The VMX flow dividers incorporate auxiliary valve blocks, which are designed to protect the section between the flow divider and the operating cylinder. All working section inlets are interlinked, which is ideal since it is generally suggested that all inlets are connected to the system circuit.

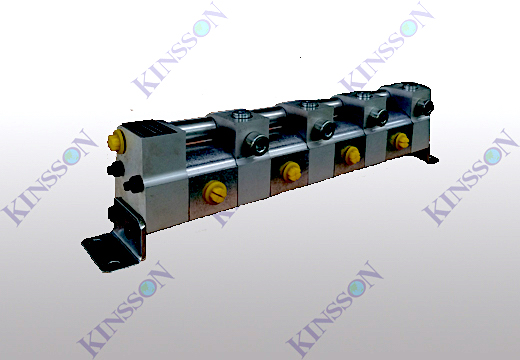

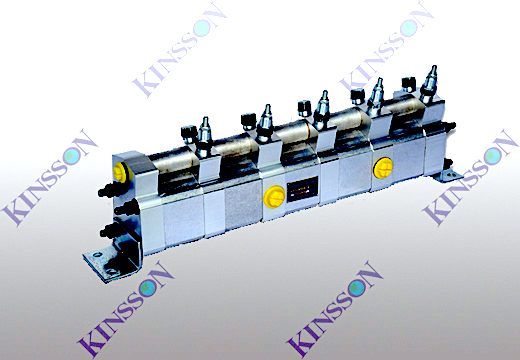

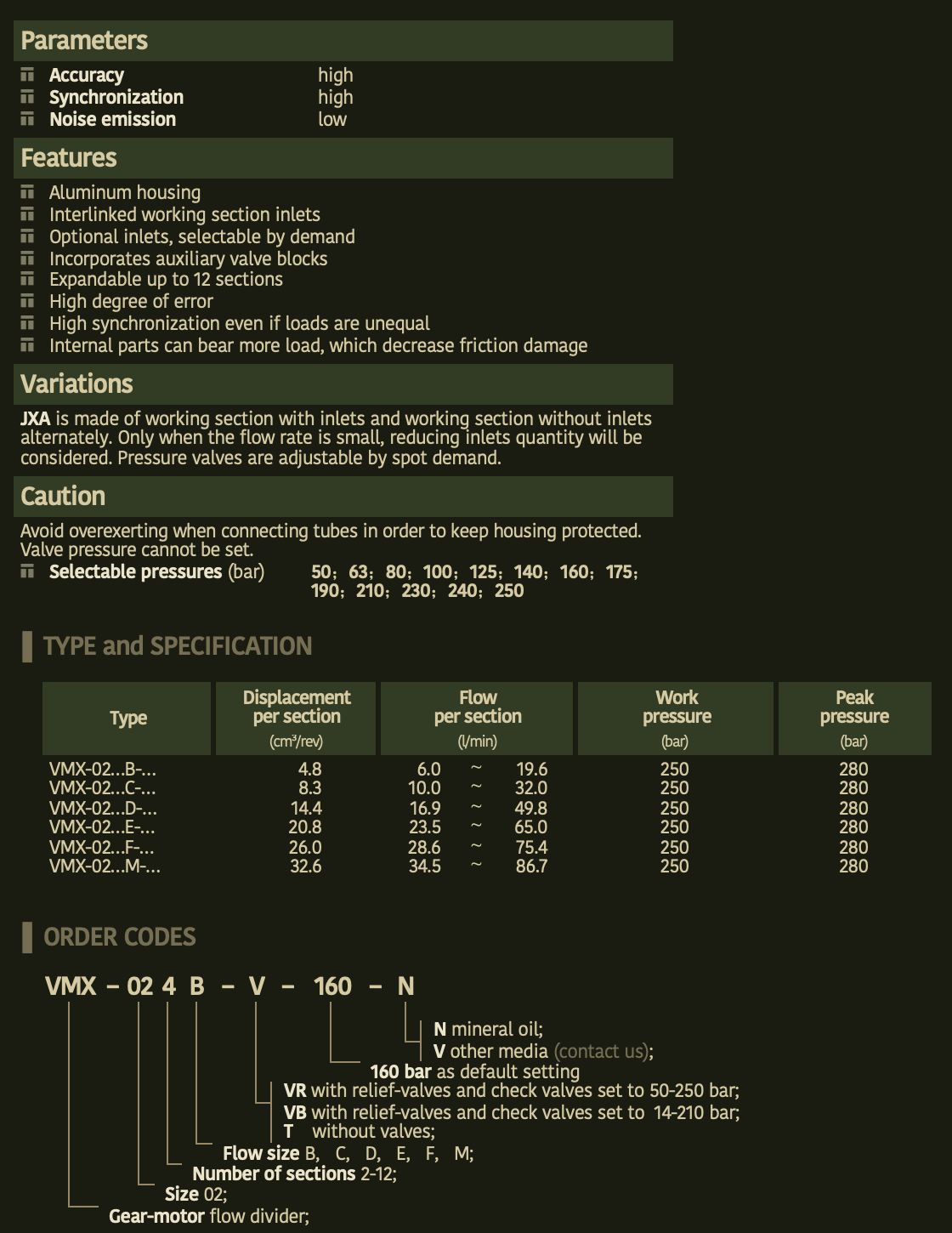

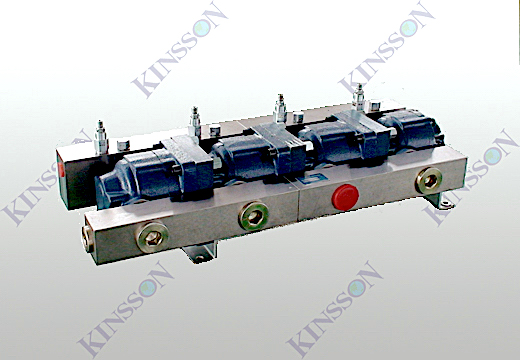

VMX-02

VMX is made of a working section without an inlet or clapboard without an inlet or end cover by progressively adding, and the inlet is on the clapboard on the end cover. The VMX flow dividers incorporate auxiliary valve blocks, which are designed to protect the section between the flow divider and the operating cylinder. All working section inlets are interlinked, which is ideal since it is generally suggested that all inlets are connected to the system circuit.

VTX-01

VTX-02

VOLUME SYNCHRONISER

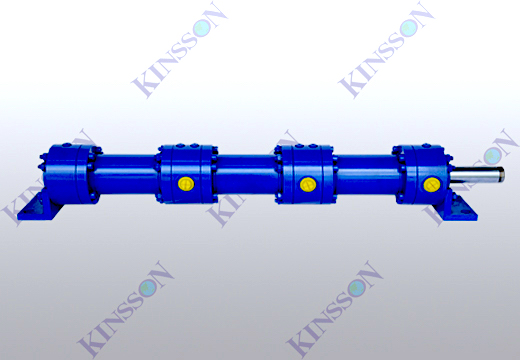

VPZ

The VPZ synchronous cylinder is a concatenation structure of several same-size hydraulic cylinders. Since the size of each section’s cavity structure is the same, the outlet flow in each chamber is also the same. JZP synchronisation cylinder adopts the most advanced Germany seal, which can obtain high synchronisation accuracy in different load cases; neither the speed control valve, synchronous valve, nor flow divider can achieve this feature. JZP synchronisation cylinder’s linear motion is different from flow divider’s rotary motion.