-

0 Comments

VEO-01 series

AXIAL PISTON FLOW DIVIDER

Kinsson’s hydraulic synchronising product is broadly applied in industries such as hydroelectric, metallurgy, engineering plants, and port machinery. Toowen produces a broad range of products that tailor to the different demands of each industry—agriculture, forestry, and construction. Therefore, our equipment is rated as the best in the global hydraulic market. Such a streamline structure of our company and industry expertise makes us the ideal fit for customers seeking a relationship beyond a manufacturer-supplier relationship but as long-term partners.

Kinsson’s hydraulic synchronising divider is overwhelmingly accepted for optimal precision, broad flow range, long useful lifetime, simplified structure, and not being bound by stroke. Such precision within a broad flow range is, remarkably, still attainable under the condition wherein unbalanced loading is needed in the circuit. As long as the design of the hydraulic circuit is done properly, the hydraulic synchronising divider is among the most easy-to-use products that can complete the job in its entirety without any additional support required.

Kinsson’s hydraulic synchronising divider is overwhelmingly accepted for optimal precision, broad flow range, long useful lifetime, simplified structure, and not being bound by stroke. Such precision within a broad flow range is, remarkably, still attainable under the condition wherein unbalanced loading is needed in the circuit. As long as the design of the hydraulic circuit is done properly, the hydraulic synchronising divider is among the most easy-to-use products that can complete the job in its entirety without any additional support required.

The hydraulic synchronising cylinder attains synchronisation through linear motion, whose inner structure differs from the flow divider. Hence, this is the perfect fit for customers seeking a higher-performing alternative to a flow divider. Here at Toowen, we offer an assortment of Kinsson hydraulic synchronising solutions that meet distinct customer needs and unique project requirements.

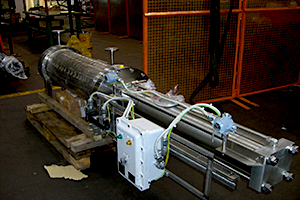

Toowen is proud to be the primary partnering entity of Silvio Fossa, an enterprise that successfully integrates experience and innovation to cater to customers’ specific needs; hence, Fossa earned the commendable leading position within the cylinder and pneumatic actuator manufacturing international industry. The strongest strength of our partner encompasses the ability to manufacture cylinders in a broad range of sizes and capabilities that meet diverse requirements concerning installation for industrial businesses.

Toowen is proud to be the primary partnering entity of Silvio Fossa, an enterprise that successfully integrates experience and innovation to cater to customers’ specific needs; hence, Fossa earned the commendable leading position within the cylinder and pneumatic actuator manufacturing international industry. The strongest strength of our partner encompasses the ability to manufacture cylinders in a broad range of sizes and capabilities that meet diverse requirements concerning installation for industrial businesses.

Fossa cylinders are comprehensively applicable worldwide. The design and manufacturing of Fossa standard cylinders strictly abide the ISO-DIN-MILL standard. The specific edge Fossa holds upon competitors lies in its ability to design and manufacture all types of non-standard cylinders according to unique customer needs. For instance, telescoping cylinders, pressure intensifiers, rotating cylinder, revolving joints, torque cylinders, etc. The manufacturer can also produce oversized cylinder for special circumstances, such as the servo screw-down cylinder of rolling mill. All of Fossa products satisfy the UNI EN ISO 9001/00-VISION 2000 standard.

Fossa cylinders are comprehensively applicable worldwide. The design and manufacturing of Fossa standard cylinders strictly abide the ISO-DIN-MILL standard. The specific edge Fossa holds upon competitors lies in its ability to design and manufacture all types of non-standard cylinders according to unique customer needs. For instance, telescoping cylinders, pressure intensifiers, rotating cylinder, revolving joints, torque cylinders, etc. The manufacturer can also produce oversized cylinder for special circumstances, such as the servo screw-down cylinder of rolling mill. All of Fossa products satisfy the UNI EN ISO 9001/00-VISION 2000 standard.

The joint venture Fossa-Kinsson was established in 2007 in pursuit of manufacturing standard cylinders in Shanghai with FKS.

LK TECHNIK has been manufacturing seals since 1979. The partner’s consolidated experience facilitates the ability to provide sealing solutions for every application. LK TECHNIK is able to produce and deliver all types of seals of all sizes up to 2000 mm per piece produced using mould. With a unique joining system, LK TECHNIK manufactures seals of any diameter above 2000 mm.

The LK TECHNIK portfolio comprises special oil seals developed for heavy industrial use, especially steel, cement, and paper mills, as well as wind turbines and rings for special situations required specifically by customers.

The LK TECHNIK portfolio comprises special oil seals developed for heavy industrial use, especially steel, cement, and paper mills, as well as wind turbines and rings for special situations required specifically by customers.