DK FLUID

- Home

- / PRODUCTS /

- DK FLUID

LUBRICATION SYSTEM

OIL-AIR

DUAL-LINE DRY OIL

PROGRESSIVE DRY OIL

DRY OIL JET

ELECTRONIC PRODUCT

ELD | ELECTROMECHANICAL LUBRICATOR

Primarily designed to compensate for the performance of conventional gas-type automatic grease lubricator. ELD encompasses superior advantages such as competitive pricing and user friendliness.

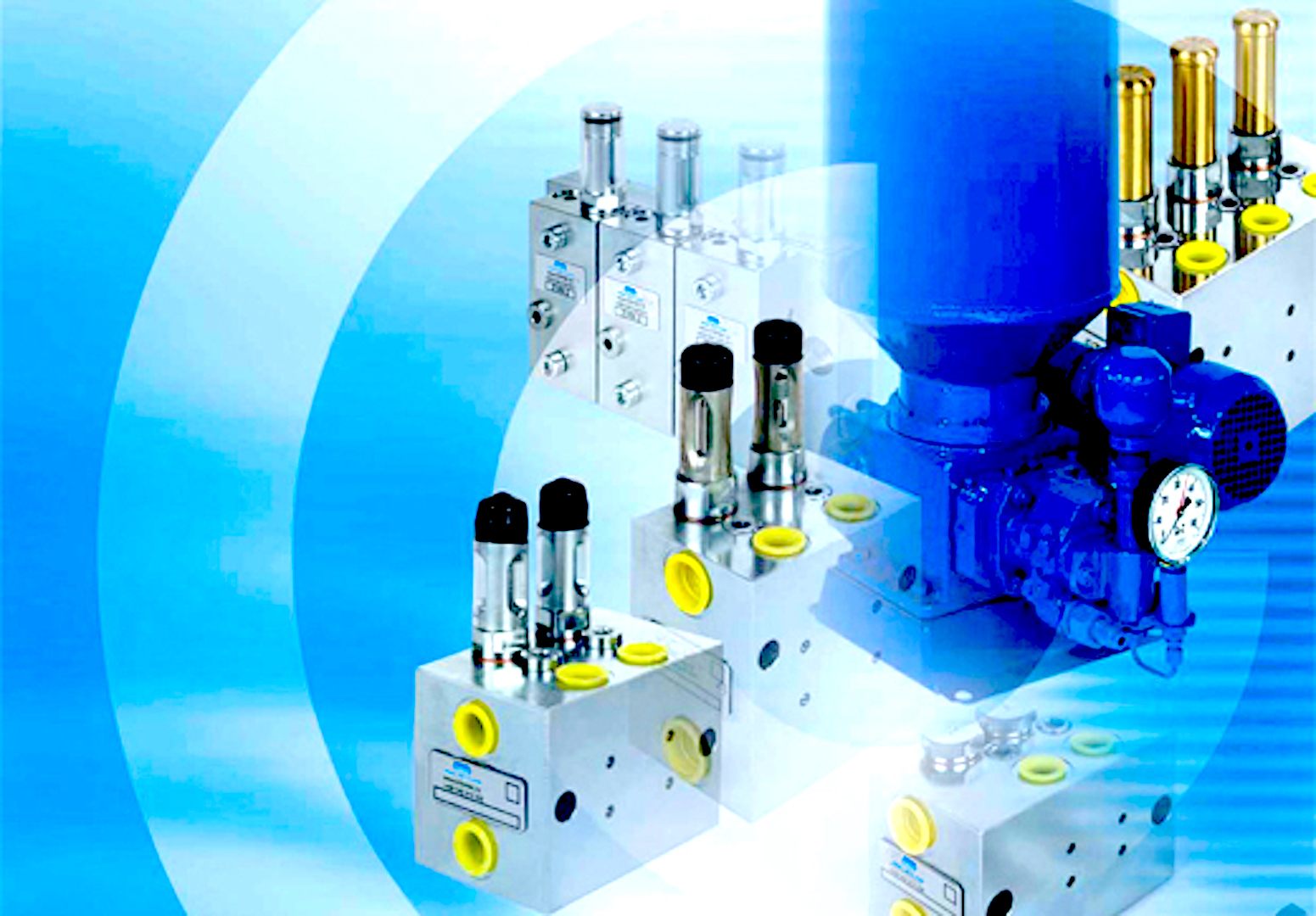

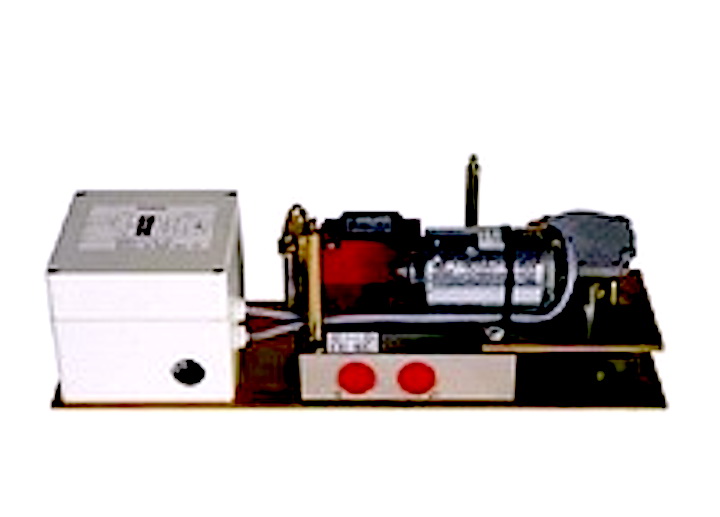

EPS | ELECTRICAL PUMP

Used as a source of pressure lubricant in circuits of dual-line central lubrication systems. EPS is substantially useful where a high number of lubricated points is needed, in addition to large circuits with extensive lengths of distribution piping and high lubricant consumption; i.e., EPS is the ideal choice for the most challenging operational conditions. EPS is usually used for permanent, or in combination with a control unit, cyclic lubrication of various machines, engineering technologies, and equipment.

The main part of the EPS lubricator is a body containing a piston pump with 4 working pistons in 2 separate pumping units. The pump is driven through a single-stage worm gearbox by a flange-mounted electric motor fitted to the side of the body. A hydraulic control unit is situated on the front of the lubrication pump body. This consists of a hydraulic change-over valve connected to the body by a slide insert, a connecting flange, a by-pass valve with a regulating nut, a pressure gauge, and an electric switch. 4 venting screws are situated on the upper part of the slide insert. A steel-plate lubricant container is also fastened vertically to the body. In order to improve plastic lubricant pumping as well as suction efficiency, there is a scraper blade in the pump container and oblique compression areas to direct the plastic lubricant into the suction space. An electric sensor to signal the minimum lubricant level is built into the lower part of the container. In addition, an electric sensor to signal the maximum lubricant level can be fitted in its upper interior. A filling hole with connecting piping is situated in the lower cross part of the storage bin. The lubricator is a unit screwed onto the foundation frame.

HZK | DIFFERENTIAL PRESSURE SWITCH

Used for monitoring the main line pressure within the dual-line centralised lubrication system. A pulse is generated when the pressure lies within the range [50, 100] bar. HZK also regulates the reversing valve of the lubrication system.

LP | PHOTOELECTRIC SWITCH

The photoelectric sensor contains an infrared light-emitting diode and a light receiver. The light from the LEDs is directed into a prism on top of the sensor. If there is no liquid, the light from the LED is reflected directly from the prism back to the receiver. When liquid immerses the prism, light is refracted into the liquid so that little to no light is received. By sensing this change, the receiver can actuate an internal electrical switch that activates an external alarm or control circuit.

LB | BYPASS MAGNETIC FLOAT LEVEL GAUGE

The magnetic float level gauge is installed on the side wall of the fuel tank. The magnetic flap above the level gauge displays the liquid level in the fuel tank using the principle of static pressure. The magnetic float rises or falls according to the change in liquid level. The magnetic scale is reversed according to the principle of magnetic attraction.

LSA | MOTOR REVERSING VALVE

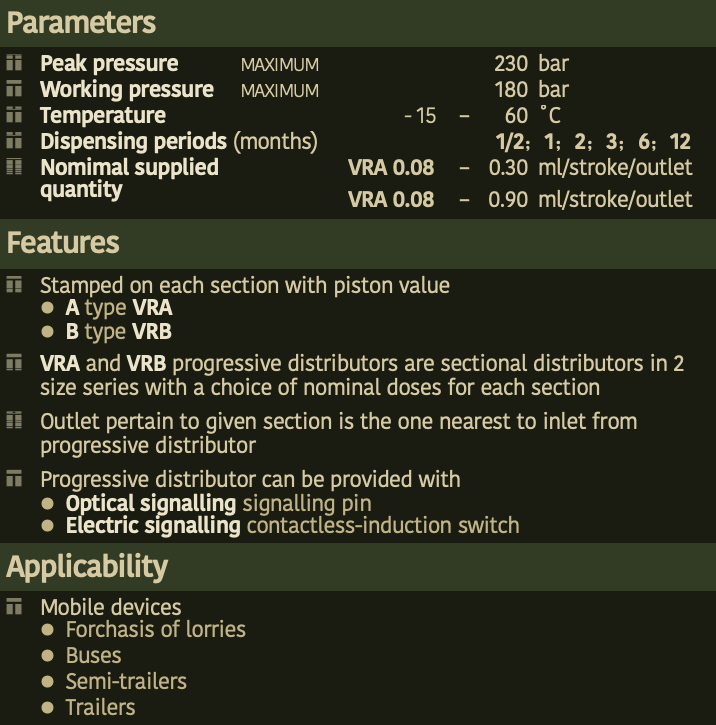

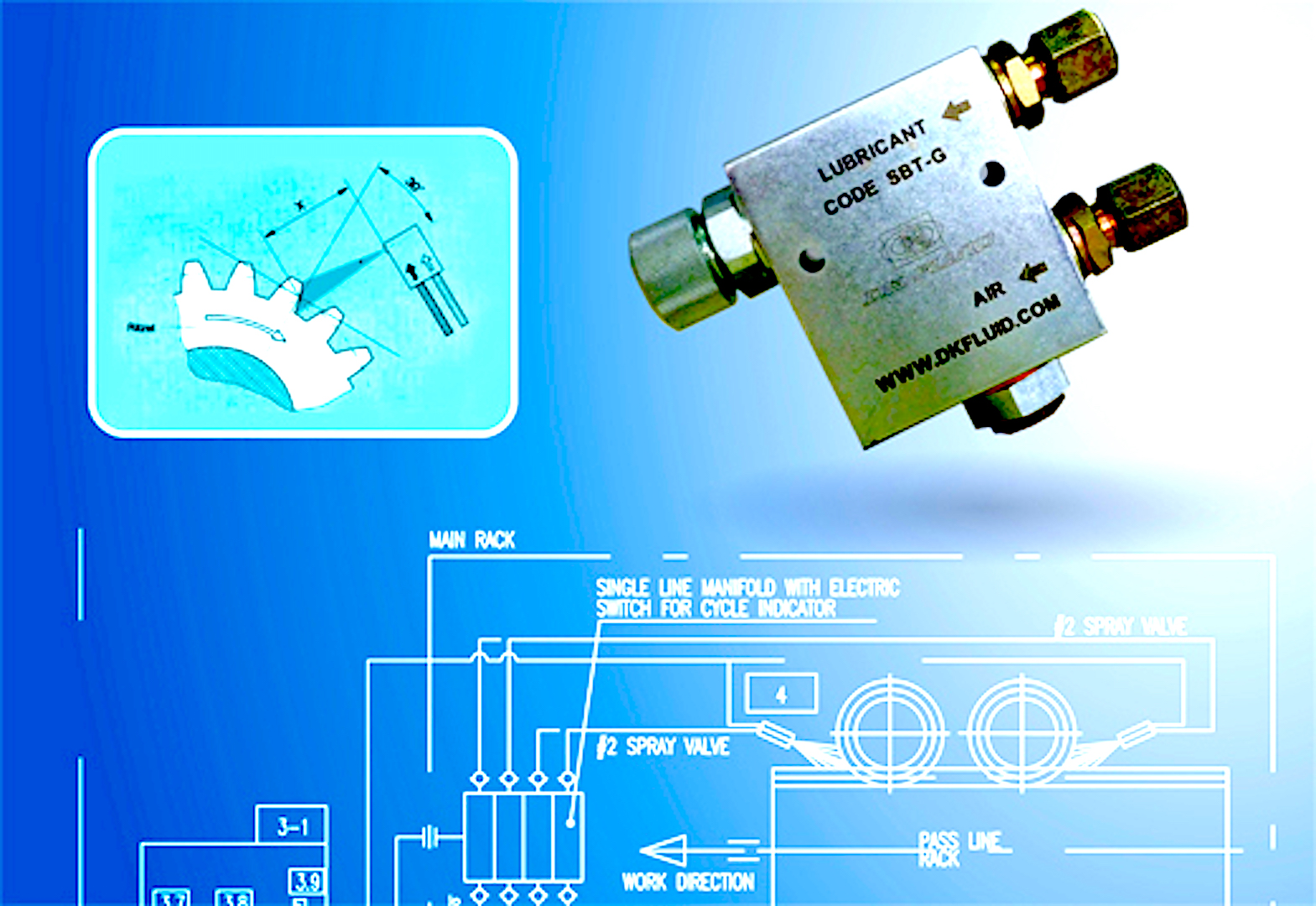

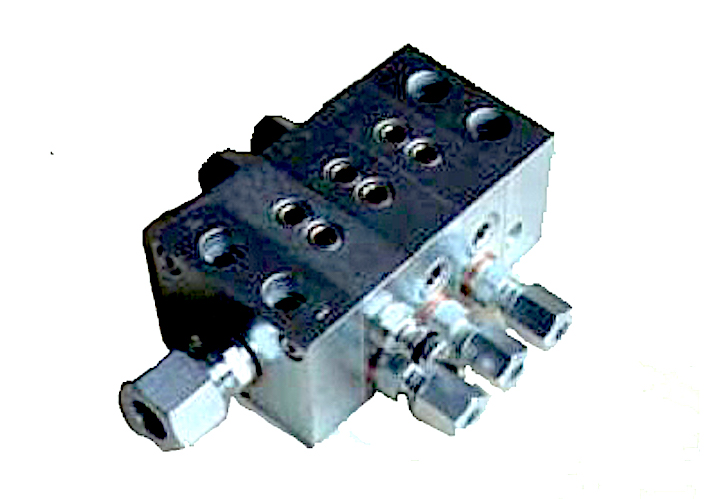

VP | PROGRESSIVE FLOW DIVIDER

A unit-construction lubricating element consists of 3 to 10 arbitrary working sections, a supply section (beginning), and a closing section (end). Each of the arbitrary working sections has at least 2 horizontal outlets on the side. Individual outlets can be mutually connected to attain the required output from a certain outlet.